Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

Fixing a hematology analyzer needs careful steps. You must treat automated hematology analyzers like delicate machines. Safety is the most important thing. Always use the instructions from the manufacturer. Automated systems help you get good results each time you run a smear. Built-in guides on automated hematology analyzers show you how to fix smear problems. Good smear preparation helps doctors make the right diagnosis and helps you get good results. Taking care of the automated hematology analyzer keeps your smear work steady. Good smear processing stops mistakes. Automated smear checks make your work steady. Automated smear review helps you find problems early. Good smear handling means less downtime. Automated smear analysis helps the machine work well.

Tip: Use the analyzer's built-in guides for every automated smear step to keep your hematology analyzer working well.

Always use the analyzer's guides and instructions to fix problems safely. Follow what the manufacturer says to solve issues the right way.

First, check the power supply, specimen quality, and error messages. This helps you find common problems like power failures or blockages fast.

Clean the sample probe and specimen pathways every day. This stops blockages and helps you get correct test results.

Calibrate the analyzer often with control samples. This keeps blood count measurements reliable and correct.

Keep a maintenance log and do regular cleaning and care. This helps stop breakdowns and makes the analyzer last longer.

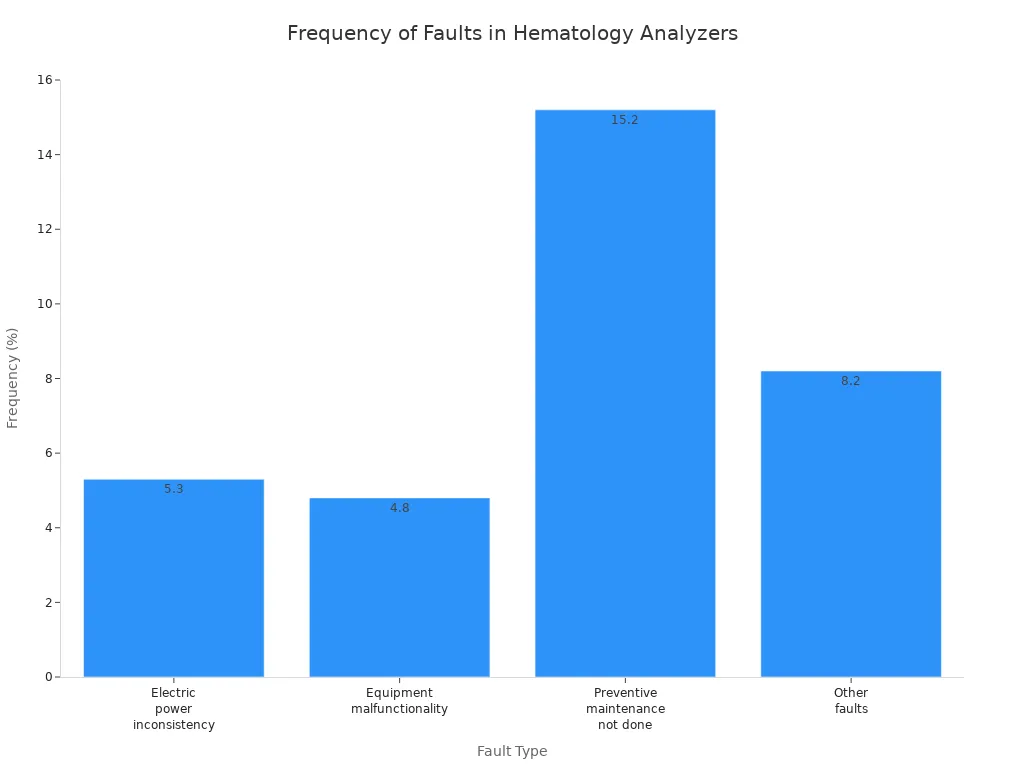

Sometimes, the hematology analyzer has power problems. These issues can stop tests and slow down diagnosis. Power problems happen in about 5.3% of cases. They often show up when maintenance is skipped. First, check the power supply and wires. The analyzer needs steady electricity for good tests. If lights flicker or the machine shuts off, there is a power problem. Use the built-in guides to find the cause fast.

The analyzer shows error messages when it finds a problem. You might see alerts for not enough specimen, clots, or broken sensor wires. These messages help you find the trouble spot. Most analyzers have tips to fix faults. Use these guides to solve problems quickly. Common faults are blockages, old pump tubes, valve issues, and reagent troubles. Always follow the analyzer's instructions for good results.

Fault Type | Frequency (%) | Notes |

|---|---|---|

Electric power inconsistency | 5.3 | Common among analytical errors |

Equipment malfunctionality | 4.8 | Slightly less frequent |

Preventive maintenance not done | 15.2 | Most frequent fault |

Reagent/sample issues | 0-8.2 | Varies |

Sometimes, results are not reliable even if you do everything right. Bad specimens, analyzer limits, or interference can cause this. Specimens with microcytosis, lysis-resistant RBCs, or hyperleukocytosis give wrong readings. Lipemia and hemolysis also mess up results. Use flags, histograms, and scattergrams to spot bad results. Look at specimens to find lipemia, hemolysis, clumps, or precipitates. Blood smear checks show abnormal cells or artifacts. To get good results, dilute specimens, use other counting ways, or estimate by smear. Reliable analyzers help doctors make better diagnoses.

Causes of unreliable automated CBC results:

Specimen-related issues (microcytosis, lysis-resistant RBCs, hyperleukocytosis)

Analyzer limitations

Interference from abnormal cells or substances

Lipemia interference

Hemolysis

Blockages stop tests and cause bad results. Poor specimen quality clogs the sample probe. Clean the probe and handle specimens better. The analyzer needs clear paths for good results. Blockages come from clots or not enough specimen. Use built-in guides to clear blockages and get good results.

Issue | Typical Source / Cause | Preventive or Corrective Action |

|---|---|---|

Clogged Sample Probe | Poor specimen quality | Clean probe, improve specimen handling |

Tip: Check specimen quality before every test. Good results need careful handling and regular maintenance.

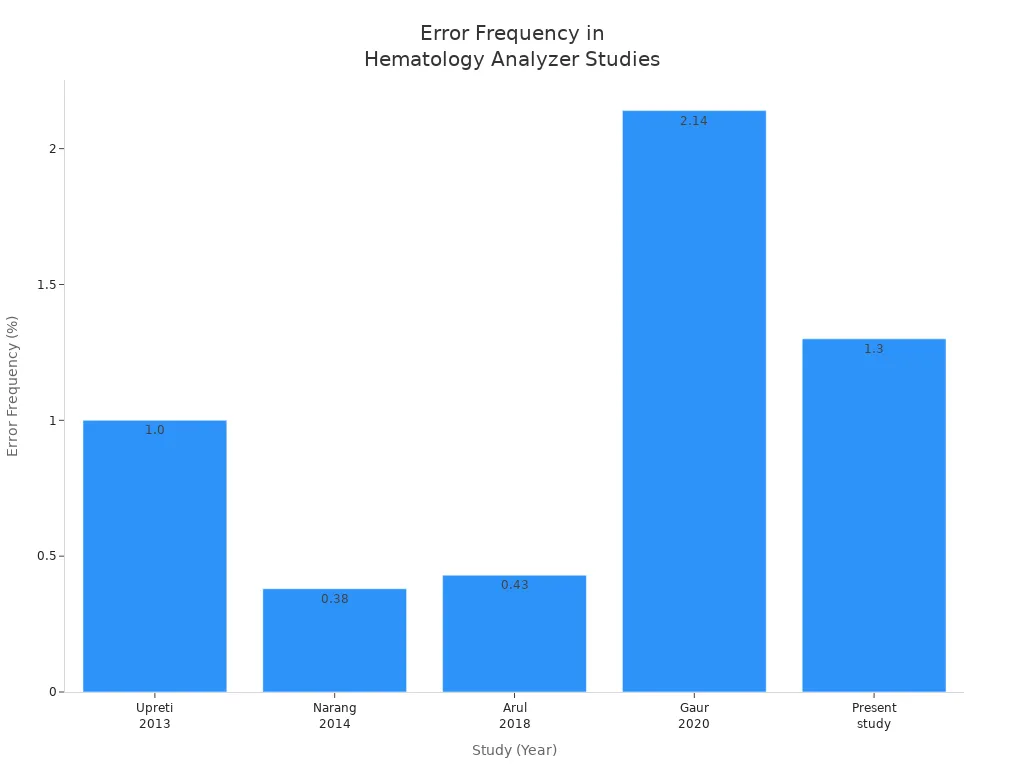

Most errors in hematology analyzers come from problems before testing. Not enough specimen, clots, and wrong labels happen most often. Reliable analyzers help you avoid these mistakes by guiding you step by step. Use troubleshooting guides to spot bad results and get good results for every specimen.

Start with simple checks first. You want your hematology analyzer to give good results every time. Follow these steps to find problems early:

Take out and clean the aspiration needle. Use a thin wire to clear any blockages. Blocked needles make results wrong and stop specimen flow.

Put all parts and tubes back in place. Make sure everything is tight.

Turn on the analyzer. Watch for sensor warnings or error messages.

Go to the maintenance menu. Run the flush and clean functions. These steps clear clots, lipemia, and hemolysis from the specimen path.

Use the zap function. This burns away blockages in the aperture.

Run a blank test. Check for leftover material or contamination.

Do quality control runs. Make sure the analyzer is set right and gives good results.

Tip: Always look at the specimen before you start. Bad specimens cause wrong results and more downtime.

Electrical problems can make the analyzer stop or give wrong results. Check these parts carefully:

Look at the power cord and plug. See if they are damaged or loose.

Check fuses and circuit breakers. Replace any that are blown.

Look at the wires inside. Sensor wires can break and cause wrong results.

Test the display and control panel. If they do not work, there may be bigger problems.

Use the analyzer's built-in tools. These help you find electrical problems fast.

Electrical Component | What to Check | Action if Faulty |

|---|---|---|

Power Cord | Fraying, loose fit | Replace |

Fuses | Blown or missing | Replace |

Sensor Wires | Breaks, corrosion | Repair or replace |

Display Panel | No response, flickering | Consult manual, replace |

Note: Always unplug the analyzer before touching wires or parts. Safety is most important.

Blockages in the specimen path often cause wrong results. Keep these paths clear for good results every time.

Clean the sample probe after each use. Clots, lipemia, and hemolysis can block the probe and cause wrong results.

Check pump tubes for cracks or old age. Old tubes can leak or collapse and give wrong readings.

Change clogged or broken nozzles. Bad nozzles stop specimen flow and make smears bad.

Look for air bubbles in the specimen. Air bubbles mess up results.

Use the maintenance menu to flush the paths. This clears old specimens and stops mix-ups.

Pathway Issue | Cause | Solution |

|---|---|---|

Clogged Probe | Clots, lipemia, hemolysis | Clean probe, flush system |

Pump Tube Failure | Aging, cracks | Replace tube |

Nozzle Blockage | Specimen debris | Replace or clean nozzle |

Air Bubbles | Shaking, poor handling | Handle specimens gently |

Callout: Always handle specimens with care. Rough handling causes hemolysis, lipemia, and wrong results.

You want good results for every complete blood count. Many things can change CBC numbers and cause wrong results.

Keep specimens cold at 4°C. Cold storage keeps CBC numbers like white blood cell counts, hematocrit, and mean corpuscular hemoglobin concentration correct. Room temperature can make results wrong.

Test specimens quickly. Waiting too long makes platelets and red blood cells stick together and gives wrong readings.

Do not shake specimens too much. Shaking makes air bubbles that mess up results.

Watch background counts. Dirty flow paths and counting holes make background counts high, especially for platelets. Clean these areas for good results.

Check the analyzer's measuring range. Numbers outside this range are not right or may not show.

Look at flagging settings. Good analyzers flag problems without too many mistakes.

Use the flagging menu to find real problems. This helps you avoid extra smear reviews.

Pick analyzers with 5-diff WBC ability. These analyzers give better and more detailed CBC results.

Tip: Always run control samples and check histograms. Good control samples help you find wrong results early.

Factor Affecting CBC Accuracy | Impact on Results | How to Obtain Reliable Results |

|---|---|---|

Storage Temperature | Unreliable CBC parameters | Store specimens at 4°C |

Processing Time | Platelet/RBC aggregation | Process specimens quickly |

Handling | Air bubbles, hemolysis, lipemia | Handle specimens gently |

Maintenance | High background counts | Clean flow paths, monitor background |

Analyzer Range | Suppressed/invalid results | Stay within measuring range |

Flagging System | Missed/false abnormalities | Use reliable flagging settings |

Analyzer Type | Granularity of WBC results | Use 5-diff analyzers |

You can use online guides and diagrams to fix things yourself. These guides show how to change sensor wires, clean nozzles, and check pump tubes. Good care and troubleshooting help you avoid wrong results and keep your hematology analyzer working well.

You need to clean your automated hematology analyzer often. Daily cleaning keeps it working well. This stops specimen contamination and blockages. Clean the outside and the sample probe every day. Flush the system with special cleaning liquids. Wipe the workspace and keep it neat. Check reagent levels so you do not run out. Teach staff how to use the analyzer and handle specimens. Write down each cleaning job for records.

Cleaning Task | Frequency | Purpose |

|---|---|---|

Clean exterior | Daily | Prevent dust and specimen residue |

Clean sample probe | Daily | Stop cross-contamination and blockages |

Flush system | Daily | Remove specimen buildup |

Soak cell pools | Weekly | Prevent smear blockages |

Clean aspiration needle | Monthly | Avoid specimen clogs |

Lubricate slide | Quarterly | Maintain automated movement |

Clean filters | Quarterly | Prevent dust-related failures |

Flush needle | Semi-annual | Remove protein and specimen deposits |

Tip: Cleaning your analyzer often helps it last longer. A clean analyzer gives good smear results and correct blood smear checks.

You must calibrate your automated hematology analyzer to get correct results. Get calibration materials and standards ready first. Follow the manufacturer's steps for calibration. Use control blood, calibration beads, or reference materials. Check calibration by running quality control samples. Write down calibration results for your records. Use trusted calibration kits to check WBC, RBC, hemoglobin, and platelets. Calibrate every day, week, or month, depending on the rules and how much you use the analyzer.

Calibration Steps:

Get the analyzer and calibration materials ready.

Run calibration samples as the instructions say.

Check results with quality control samples.

Write calibration results in your maintenance log.

Note: Calibrating often stops mistakes in automated smear analysis. It makes sure every specimen gives correct results.

You keep your automated hematology analyzer safe by doing preventive care. Clean the specimen processing areas every day. Update the software when needed. Only use parts and supplies from the manufacturer. Have a professional service the analyzer once or twice a year. Keep a log of all cleaning, calibration, and repairs. Teach staff to do small maintenance jobs. Check how the analyzer works often and change your care plan if needed.

Maintenance Interval | Recommended Tasks Summary |

|---|---|

Daily | Clean aspiration needle, run blank testing, perform quality control, proper shutdown and cleaning |

Weekly | Use cleaning solution, soak chambers, flush and wash, zap aperture |

Monthly | Power off, clean workstation, dust circuit boards, check cables |

Semi-Annual | Engineer servicing, clean systems, replace filters, flush needle, run QC |

Callout: Keeping a maintenance log helps you find problems early. You can stop breakdowns and keep your analyzer ready for every specimen and smear.

You can keep your hematology analyzer working well with regular checks. Use the built-in guides to fix hard problems fast. These guides help you spend less time fixing and trust your results more. To get the best results, use a troubleshooting checklist:

Look for sample problems like agglutination or fibrin crystals.

Make sure reagents are good and change them if needed.

Check for electromagnetic interference and see if grounding is right.

Clean the detection chambers, valves, and pipelines often.

Check pumps and valves for leaks or other problems.

Handle blood samples the right way.

Use the correct anticoagulants every time.

Calibrate diluters and suction tubes as needed.

Mix samples well before testing.

Pick high-quality reagents for each test.

Keep samples sealed and test them within 6 hours.

Follow all quality control steps carefully.

Keep this checklist close. It helps you find problems early and keeps your analyzer ready for every test.

Look at the power cord and plug. Check if the fuse is good. Try plugging it into another outlet. If it still does not turn on, call technical support.

Calibrate every day or every week. Follow the schedule from the manufacturer. Use control samples to make sure results are right.

Frequent errors can mean probes are dirty. Old reagents or sensor problems can also cause errors. Clean the analyzer well. Put in new reagents. Look for wires that are loose.

No, you cannot use just any cleaning solution. Only use cleaning solutions the manufacturer says are safe. Other cleaning products can hurt the analyzer.

Handle specimens with care. Clean the probe after each test. Look for clots before you load samples. Clean often to stop blockages.