Views: 0 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

When you pick a washer disinfector, some things are very important. You must choose one that fits your needs now and in the future. You should think about cost, safety, and how well it cleans. In healthcare, the total cost over time is as important as the first price.

Key considerations:

Capacity and scalability help work go smoother and make things easier.

Things like maintenance and compatibility can cause more or less downtime.

Cost, including setup and supplies, affects how much you spend.

Average Lifespan | Maintenance Costs | Utility Consumption | Productivity |

|---|---|---|---|

8-10 years | Goes up over time | Older ones use more water | New ones clean faster |

Pick a washer disinfector that matches your daily needs and future plans. This helps your work go smoothly and stops delays.

Use cleaning indicators and the right cycle settings. This makes sure your instruments get cleaned and disinfected well each time.

Choose a washer disinfector that works with your instrument types and materials. This keeps your tools safe from harm and keeps everyone safe.

Plan your space and utilities before you install the washer disinfector. This helps it work safely and well, and stops expensive problems.

Check your washer disinfector every day and use good technical support. This keeps it working well and helps it last longer.

You need to pick a washer disinfector that matches your daily needs. First, count how many trays and instruments you use each day. If your facility has lots of cases, you need a washer disinfector for big loads. Flexible racks help you fit many shapes and sizes of instruments. You can use adjustable shelves and modular baskets for both large trays and small tools in one cycle. This makes your work easier and stops delays.

Tip: Pick racks you can change around. This helps you adjust fast when your instrument mix changes.

A table can help you see what load volume you need:

Daily Cases | Trays per Case | Total Trays per Day | Suggested Washer Disinfector Size |

|---|---|---|---|

10 | 3 | 30 | Small to Medium |

25 | 5 | 125 | Medium to Large |

40+ | 8 | 320+ | Large, High-Capacity |

Throughput shows how quickly you can clean and reuse instruments. Busy healthcare places need a washer disinfector that works fast. You should think about how many instruments you have and how you load them. Three-level racks and standing up instruments help water reach everything. If you put too many items in or load them wrong, it slows down cleaning and does not clean well.

Ask yourself these questions:

How many cases do you have each day?

Do you often have backlogs?

What surgeries do you support?

If you think you will grow or get new technology, plan for more capacity now. This stops slowdowns and helps you work faster. The best washer disinfector matches load size, speed, and rack design. It helps you meet your needs now and later.

You need a washer disinfector that cleans well every time. Cleaning indicators like PNCL, Wash-Checks, and TOSI help you check cleaning. Put these indicators in the hardest spots to clean, called the Process Challenge Location (PCL). Test these spots every day and week to find problems early. Just looking at instruments can miss hidden dirt. Cleaning indicators show issues sooner and more clearly. Standards like ISO 15883-5 help you check and prove cleaning works.

Tip: Use cleaning indicators in different places inside the washer disinfector. This helps you find problems before they can hurt patients.

A washer disinfector must give strong disinfection before sterilization. You want it to kill tough germs well. The table below shows how a washer disinfector cycle lowers dangerous bacteria and spores:

Evidence Aspect | Details |

|---|---|

Pathogen Reduction Results | MRSA and VRE drop to levels you cannot detect; C. difficile spores drop a lot |

Washer/Disinfector Process Steps | Pre-wash, detergent wash, ultrasonic cleaning, thermal rinse, drying |

Effectiveness Summary | Very good at killing bacteria and spores before sterilization |

Additional Notes | Heating to 180°F in the washer disinfector and 270°F in the sterilizer kills germs |

You can trust the washer disinfector to help clean and get tools ready for sterilization.

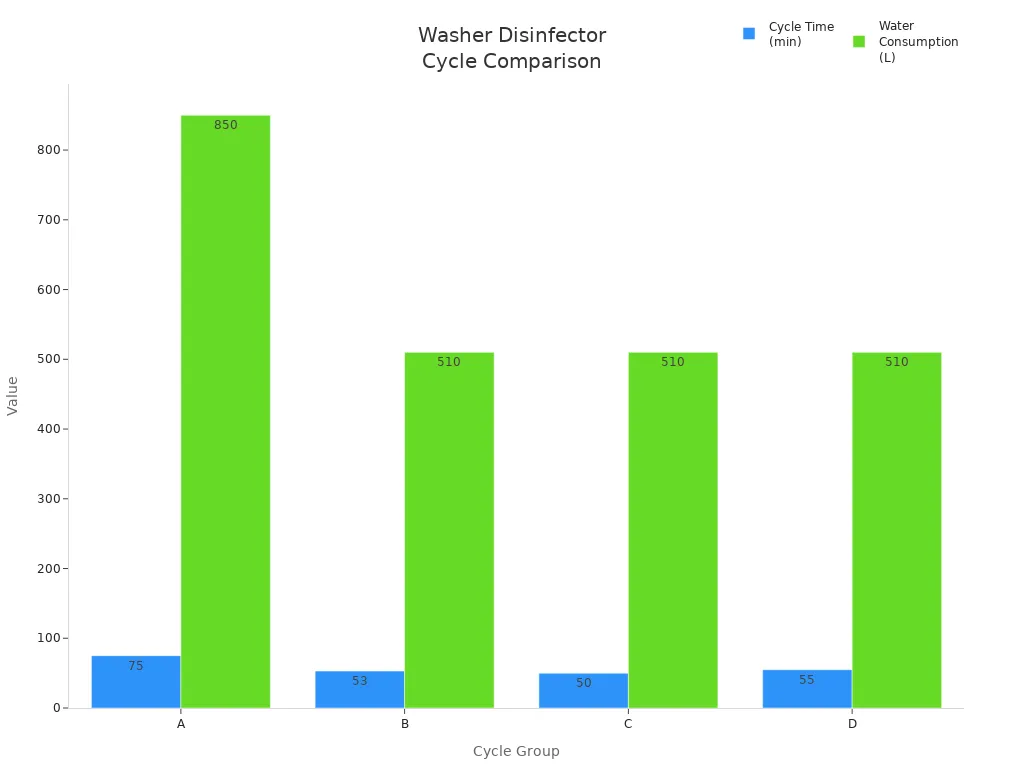

Different washer disinfector cycles change how well things get cleaned and disinfected. Cycle settings include time, temperature, detergent amount, and how the machine moves. Higher washing temperatures clean better than longer cycles or more detergent. The chart below shows cycle time and water use for four cycle types:

Vacuum-assisted boiling cycles use pressure changes and pulses to clean tricky tools. These cycles clean inside tubes and joints better than normal spray cycles. Pick cycle types that fit your tools and cleaning needs. The right cleaning and disinfection steps make sure tools are safe and ready for sterilization.

You need to pick a washer disinfector that matches your instruments. Every device needs a certain way to get clean. Some washer disinfectors are good for general surgical instruments. Others are made for laboratory glassware or endoscopes. Endoscopes are fragile and have a special shape. They need their own washer disinfector. Dental washer disinfectors are for dental clinics. They help clean dental tools the right way.

Here are some common instrument types that need special washer disinfector features:

General surgical instruments like scalpels, forceps, and scissors

Hinged tools that need oil to move smoothly

Anesthesia and respiratory equipment like breathing tubes and masks

Basins, bowls, containers, and sterilization trays

Endoscopes, which need special cycles and leak tests

Check what you need to clean before you choose a washer disinfector. If you clean many kinds of items, you need racks that can change and cycles you can adjust. This helps you follow strict cleaning rules and keeps your work moving fast.

Not every material can go through washer disinfector cycles. Some metals and coatings can rust or lose their shine during cleaning. The most at-risk materials are brass, zinc, copper, nickel or silver plating, aluminum coatings, bronze, plain steel, and galvanized iron. Disinfectants like hydrogen peroxide or peracetic acid can hurt these surfaces.

To keep your surgical instruments and other devices safe, always follow the manufacturer's instructions. Use test strips to check if the disinfectant is strong enough. Stay away from chemicals that can damage soft materials. Leak testing is very important for endoscopes. It helps you find tiny leaks that let water in and break inside parts. If you find a leak, do not use that instrument on patients.

Tip: Some items still need to be cleaned by hand, even after using a washer disinfector. This step helps keep devices safe and working well.

A table can help you see which materials need extra care:

Material Type | Risk in Washer Disinfector | Precaution Needed |

|---|---|---|

Brass, Copper, Bronze | High (corrosion) | Avoid harsh chemicals |

Aluminum Coatings | Medium (dulling) | Use mild detergents |

Steel, Galvanized Iron | High (rust) | Dry thoroughly |

Plastics | Warping at high temp | Lower drying temperature |

You keep your surgical and dental instruments safe by picking the right washer disinfector and following the best ways to clean them.

You need to think about space before you install a washer disinfector. Every hospital or clinic is different. The right space depends on how big your building is. It also depends on how many beds you have. You should also count how many instruments you clean each day. There is not one rule for everyone. Make your workflow so dirty tools move to clean and then to sterile areas. Use walls or barriers to keep these areas apart and safe.

Think about these things when you plan your space:

Give staff enough room to walk and work safely.

Use tables that can go up or down to help staff.

Add windows or sunlight if you can. Good light helps staff see better.

Try to make the room quieter. Washer disinfectors can be noisy.

Ask your supplier for AutoCAD or BIM symbols. These help people design the room.

A good space helps your work go smoothly and keeps staff happy.

Planning Factor | Why It Matters |

|---|---|

Forward-moving workflow | Stops germs from spreading |

Physical barriers | Keeps clean and dirty areas apart |

Ergonomics | Helps staff feel less tired |

Lighting | Makes it easier and safer to see |

You need the right power and water for your washer disinfector. Pick single-phase or three-phase power. Your supplier can help you choose. Hard-wire the machine and use a switch to turn it off safely. Check your water pressure and make sure the water is clean. Some machines need water softeners to stop buildup.

Drainage is very important. Washer disinfectors let out hot water, sometimes up to 93°C. Use pipes that can handle heat and have tight seals. Regular pipes can melt or leak from the hot water. Bad drainage can cause leaks or even floods.

Tip: Always check what power and drainage you need before you install. This helps you avoid problems and keeps your washer disinfector working well.

A good setup keeps your equipment and building safe.

You want a washer disinfector that keeps work moving. Cycle duration means how long it takes to clean, disinfect, and dry tools. Modern washer disinfectors have three main steps. First, they flush with water to get rid of dirt. Next, they use moist heat to kill germs. Last, they dry the tools so you can use or store them. Each step depends on time, temperature, water flow, and detergent strength. Faster cycles give you instruments back sooner, but you need to check if the machine can handle your load.

A modern washer disinfector can save about 10 minutes per cycle compared to cleaning by hand. But the total time for reprocessing has other steps too. Here is a breakdown:

Stage | Approximate Time | Notes |

|---|---|---|

Decontamination & manual cleaning | Around 45 minutes minimally | Combination of manual cleaning and automated washer-disinfector cycle |

Automated washer-disinfector cycle saving | About 10 minutes saved | Automated cycles reduce cleaning time compared to manual methods |

Assembly & visual inspection | Variable | Depends on device condition, staffing, workflow, and experience |

Moist heat/steam sterilization | 30-45 minutes minimally | Depends on sterilizer cycle, model, and load size |

Cooling time after sterilization | Up to 2 hours preferred | Recommended by guidelines; minimally 30 minutes but preferably 2 hours |

Total minimum reprocessing time | 3.5 to 4 hours | Includes all stages: cleaning, sterilization, and cooling |

Tip: Pick a washer disinfector that fits your daily case load. Faster cycles help, but you also need to plan for sterilization and cooling.

A washer disinfector does more than just clean tools. It changes how your team works. Automation helps stop mistakes and keeps cleaning quality high. You do not have to check every step as much. Some washer disinfectors use AI to spot problems and remind you about maintenance. This keeps machines working and lowers downtime.

You also get better records. Digital tracking helps you follow rules and show you cleaned everything right. Newer models use less water and energy, which saves money and helps the planet.

Automation lowers mistakes and improves quality.

AI and real-time checks help stop downtime.

Digital records help with rules and audits.

Using less water and energy saves money.

When you choose a washer disinfector, you help your team work faster and safer. You also get ready for more cases and new technology later.

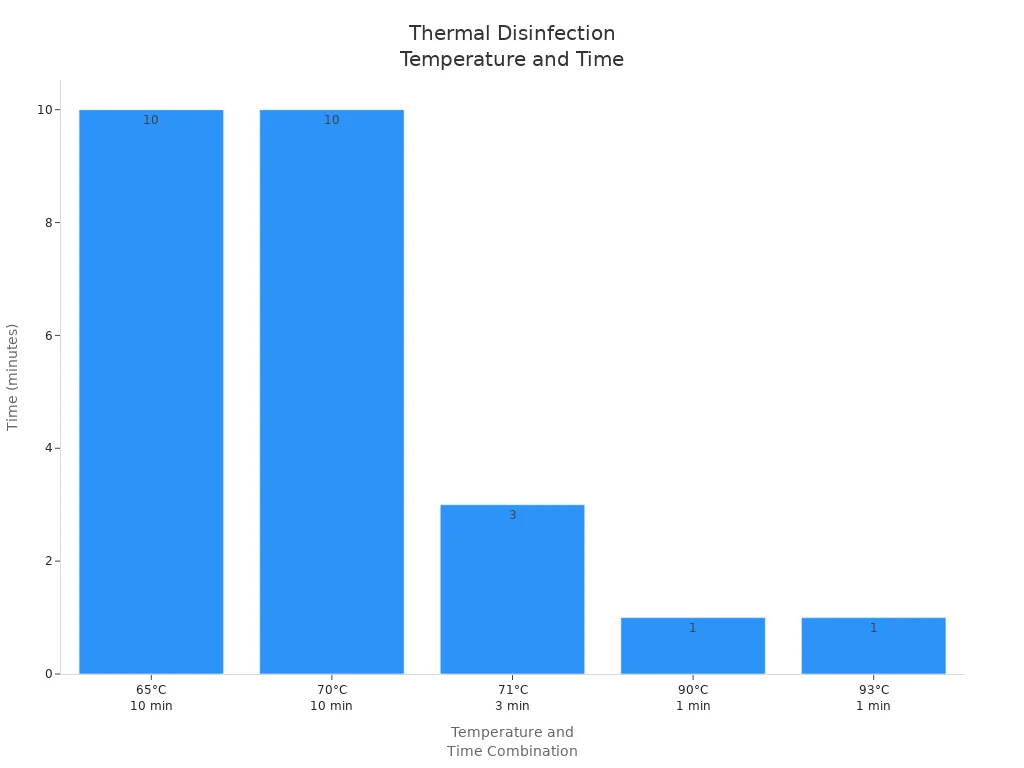

You need to check if your washer disinfector gets hot enough. Thermal disinfection uses wet heat to kill germs before sterilization. Different germs die at different temperatures and times. The table below shows what temperature and time you need:

Temperature Range (°C) | Time Duration | A0 Value | Application/Notes |

|---|---|---|---|

65 - 100 | Variable | N/A | General thermal disinfection range; most vegetative bacteria and fungi inactivated above 65°C. |

65 | At least 10 minutes | 60 | Bedpan washers (ISO 15883-3); effective for many pathogens but some resistant viruses require more. |

70 | 10 minutes | 60 | Suggested minimum for some pathogens; nonenveloped viruses require >70°C for effective inactivation. |

90 | 1 minute | 600 | Surgical instruments (ISO 15883-2); high-level disinfection standard. |

93 | 1 minute | N/A | Laundry thermal disinfection example. |

71 | 3 minutes | N/A | Laundry thermal disinfection example. |

>100 | Variable | N/A | Required for bacterial spores such as Clostridium difficile. |

Note: The A0 value tells you how well the washer disinfector kills germs. Higher heat or longer time works better. ISO 15883 gives rules for what settings to use for each tool.

You can look at the chart to see which temperature and time work best:

For most loads, you should use these settings:

93°C for 1 minute

71°C for 3 minutes

65°C for at least 10 minutes

These settings help you get high-level disinfection before sterilization. Always check your washer disinfector manual for the best cycle.

You need to use the right chemicals in your washer disinfector. The wrong detergent can hurt the machine or your tools. Many washer disinfectors, like the Tuttnauer TIVA-8, have pumps for alkaline detergents and neutralizers. This setup gives the right cleaning power every time. Some machines need reverse osmosis water to stop stains and pitting on tools.

Different materials need different chemicals. Stainless steel, aluminum, and titanium all react differently. Alkaline detergents clean well, but you need neutralizers to protect soft surfaces. The Miele white paper says strong chemicals can cause corrosion. Always use process chemicals that match your instrument type. After washing, neutralizing and rinsing keep your tools safe for sterilization.

Tip: Always follow the washer disinfector and instrument maker's instructions. This helps you avoid damage and keeps your sterilization process safe.

You need to keep yourself and your team safe. Modern washer disinfectors have many safety features. These features help lower risks in hospitals and clinics. They help stop injuries and keep you away from germs.

Full automation does every step for you. You do not touch dirty tools as much, so you stay safer.

The thermal disinfection step kills most germs before you open the door. This lowers the chance of spreading infection.

Proprietary chemical formulations make cleaning strong and safe. They clean tough dirt but are still safe for workers.

The design makes your job easier and safer. You do not have to handle dirty tools for long.

Pre-soaking tools in the reprocessing area helps a lot. It means you scrub less by hand and stay safe from sharp tools and splashes.

Tip: Always follow your workplace's safety rules. Wear gloves and eye protection when you load or unload the washer disinfector.

You must pick a washer disinfector that follows strict rules. In the United States, ISO 15883 is the main standard for washer disinfectors. Groups like the CDC and FDA make sure infection control rules are followed. Programs like the California HAI Program help improve infection control.

In Europe, you must follow the European Medical Device Regulation (EU MDR 2017/745). This law replaced the old Medical Device Directive. Now, it needs stronger checks before and after products are sold. European washer disinfectors must also meet EN ISO 15883 standards. Makers often get certificates like the EU Quality Management System (QMS) Certificate and ISO 13485:2016. These show the washer disinfector meets the newest safety and infection control rules.

Wassenburg Medical has both EU MDR and QMS certificates. This shows they follow the rules and keep cleaning safe for hospitals. Modern washer disinfectors record data and help you track cleaning cycles. This makes it easier to pass audits and follow the rules.

You should check your washer disinfector every day. This helps it work well and last longer. Daily checks help you find problems early. This protects your machine and keeps it safe. When you follow a routine, you make sure it cleans right.

Here are the most important things to do each day:

Look at the washer disinfector for damage or worn parts. This stops safety problems and sudden breakdowns.

Clean the washer disinfector and the area around it. Getting rid of dirt and spills keeps your space safe and stops germs from spreading.

Watch the cleaning cycles. Make sure each one works right and gets hot enough.

Follow the manufacturer's instructions every day. This helps the washer disinfector work smoothly.

Write down your daily checks in a logbook. Good records help you fix problems fast and show you follow safety rules.

Check handwashing sinks and emergency stations. Keeping these clean helps everyone stay healthy.

Tip: Look for things like leftover dirt, white spots, or extra disinfectant. These can make cleaning worse and mean you need a pro to help.

You might see problems like dirt buildup, white spots, or leftover chemicals. If you see these, plan a deep clean or call a technician.

Common Issue | What You Should Do |

|---|---|

Organic buildup | Clean filters and trays |

Mineral deposits | Use water softener |

Chemical residue | Rinse and check detergent |

You need good technical support to keep your washer disinfector working. Fast help from experts means less waiting and safer care. When you have skilled technicians, you get quick repairs and real parts.

Fast service helps you fix problems before they stop your work.

Regular checkups catch problems early and help your washer disinfector last longer.

Emergency repair is there all day and night to keep your schedule on track.

Service plans often check if your washer disinfector is working right and if the water is clean. These steps help you meet safety rules.

Online service lets you see repairs and logs. This makes it easier to pass checks and follow rules.

Working with a trusted service team helps you feel calm. You know your washer disinfector will work when you need it.

You have many things to think about when picking a washer disinfector. You might need one with the right size, fast cycles, and a good price. Make a checklist to help you choose the best one for your needs:

Check how much it can hold

Look at how long each cycle takes

Make sure it works with the right heat and chemicals

See if it has safety parts

Think about how much care and money it needs

Challenge | What Happens | How to Fix It |

|---|---|---|

Capacity | Changes how well it cleans | Pick racks that fit your needs |

Water/Energy Use | Makes it cost more | Pick models that save resources |

Talk with your team and the people who sell the machines. They can help you pick what works best now and later.

A washer disinfector washes and disinfects tools. It uses water, heat, and chemicals to clean. A sterilizer kills every germ, even spores. You need both machines to keep medical tools safe.

Check your washer disinfector every day for dirt or damage. Get a professional to check it every 6 to 12 months. Always follow the manufacturer's instructions for the best care.

No, you cannot use just any detergent. Only use detergents that are approved for your machine. The wrong detergent can hurt your tools or the washer disinfector. Always read the manual to find the right products.

Look in the manual to see what the error code means. Try turning the machine off and on again. If the error does not go away, call technical support. Do not use the washer disinfector until the problem is fixed.